Relied On Drywall Fort Worth Specialists for Seamless Outcomes

Relied On Drywall Fort Worth Specialists for Seamless Outcomes

Blog Article

Drywall Setup Made Easy: Tips for Perfect Results

Drywall installation is commonly perceived as a complicated task, yet with the best method and knowledge, it can become a convenient venture. Choosing high quality materials and preparing the installment location are important very first steps that establish the structure for success. Additionally, understanding techniques for reducing, hanging, and completing drywall can substantially influence the outcome. As we explore these necessary tips, you may discover that also the smallest adjustments in your method can bring about incredibly boosted results, leaving you to take into consideration just how these practices can transform your next job.

Picking the Right Materials

Picking the suitable products for drywall setup is essential to accomplishing a durable and cosmetically pleasing surface. drywall contractor. The main part, drywall sheets, typically been available in numerous thicknesses, with 1/2-inch sheets being common for interior walls. For areas requiring added wetness resistance, such as kitchen areas or restrooms, think about using environment-friendly board or cement board, which are specially made to stand up to humidity

In addition, picking the appropriate fasteners-- either screws or nails-- is essential for securing the drywall to the framework. Drywall screws are typically preferred for their holding power and minimized threat of standing out. Consider the finishing touches such as primer and paint, which not only enhance the appearance however additionally protect the drywall from dampness and wear.

Preparing the Installment Location

Prior to beginning the drywall installation process, it is necessary to prepare the installation location completely. This preparation entails a number of critical actions to make sure a smooth and successful task. Clear the location of any type of furnishings, home appliances, or blockages that might prevent gain access to. A clean work space reduces the threat of damage to existing products and allows for reliable movement throughout installation.

Following, examine the wall surfaces and ceiling for any type of flaws, such as cracks, holes, or mold. Address these problems ahead of time; spot any damages and enable adequate time for repair work to completely dry. Additionally, ensure that electric outlets, switches, and plumbing are appropriately positioned and made up, as this will affect drywall positioning.

Consider the environmental problems too. A stable temperature and humidity degree are crucial for optimum attachment and efficiency of the drywall products. If essential, make use of a dehumidifier or heater to develop ideal conditions.

Trimming and Hanging Drywall

The trick to reliable drywall installation lies in the precise cutting and dangling of the panels. Begin by gauging the room precisely, considering any obstructions such as electric outlets or home windows. Utilize a straight edge and an utility blade to rack up the drywall along your dimensions, then break it along the scored line for a clean break. For even more detailed cuts, such as around electrical outlets, a drywall saw can be used for precision.

Constantly function from the top down and delegated right, ensuring that you preserve a staggered pattern to improve stability. Properly hanging the drywall sets the structure for a smooth coating, ultimately bring about exceptional lead to your drywall task.

Taping and Mudding Methods

While correct cutting and hanging of drywall establishes the stage, the next crucial action entails mastering taping and mudding methods to make certain a seamless surface. Insulation is essential for strengthening joints and protecting against cracks; it includes installing tape right into the used joint substance (mud) Start with a high quality fiberglass or paper tape, using the tape over the joint and pushing it right into the damp mud using a taping knife, guaranteeing no air bubbles continue to be.

As soon as the tape is in place, apply a thin layer of joint compound read the article over the tape, feathering the edges to produce a smooth shift to the drywall surface area. Permit this visit the site layer to completely dry completely before sanding it lightly to remove imperfections. Repeat this process, applying additional coats of mud as essential-- usually 2 to 3 layers-- while slowly broadening the application location with each layer to accomplish a seamless look.

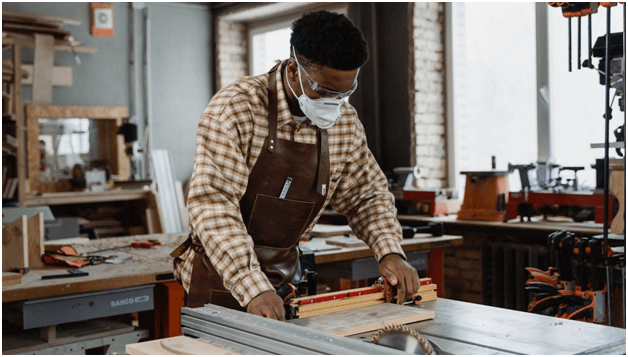

After the final coat dries out, sand the surface area with a fine-grit sandpaper till smooth. drywall installation. Keep in mind to use a mask during sanding to avoid inhaling dirt fragments. Understanding these taping and mudding strategies is essential for attaining a professional-quality surface in your drywall setup

Completing Touches for Perfection

Achieving a remarkable drywall installment exceeds taping and mudding; it culminates in the finishing touches that boost the general appearance. These final actions are critical in making sure a professional-grade surface that enhances the aesthetics of your room.

Begin by fining sand the dried joint compound to develop a smooth surface. Use a fine-grit sandpaper and a fining sand block or pole sander for optimum control. Pay specific attention to sides and edges, as these areas tend to require even more careful work. After fining sand, clean down the wall surfaces with a damp towel to eliminate any dirt particles, making certain a clean surface area for paint.

Next, use a guide specifically created for drywall. This action is vital, as it aids seal the joint substance and provides an uniform base for the overcoat. Once the guide dries out, examine for any kind of imperfections, and retouch as required.

Conclusion

In final thought, effective drywall installment pivots on the mindful option of products, thorough preparation of the installation area, and accurate execution of cutting and hanging techniques. Mastery of taping and mudding processes is important for accomplishing a smooth finish.

Drywall setup is typically viewed as a complicated job, yet with the ideal technique and understanding, check my reference it can end up being a workable venture.Choosing the ideal products for drywall installment is crucial to achieving a sturdy and cosmetically pleasing coating.Prior to beginning the drywall installment procedure, it is crucial to prepare the installment location completely. Mastering these taping and mudding strategies is important for attaining a professional-quality surface in your drywall installation.

In verdict, effective drywall setup pivots on the mindful choice of materials, thorough prep work of the setup area, and specific implementation of cutting and hanging strategies.

Report this page